-

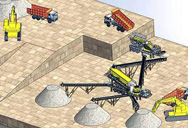

Мобильная дробилка

- запасные дробилки части сделанные в южной африке

- мобильные дробилки ey900

- чертеж режущая ножевая мельница sm

- мобильная конусная дробилка в южн

- поворотный стиральная кварцевый песок

- концевых фрез преимущества

- тонн в час дробилка завод

- ТЭО для шаровой мельницы

- стиральная машина для руды

- порядок сборки привода мобильной дробилки ciros lt116

- мельницашаровая мельница объемом м видео

- мини влияние рок дробилки

- медной руды дробильная установка в Омане

- фото работы виброгрохот по шнекам

- iron process ball mill

<щековая дробилка сколько продать

ReviewNew insights into ball-milled zero-valent iron

2023年1月20日 The development of the ball-milling method in the iron chemistry field. Since its introduction in the late 1960s, significant progress has been made in the study

Read More

A Review of the Grinding Media in Ball Mills for Mineral

2023年10月27日 Ball mill efficiency directly affects the cost of mineral processing. Grinding media play a vital role in enhancing the efficiency of a ball mill through their direct effect

Read More

Optimization of Solids Concentration in Iron Ore

2019年6月18日 The paper demonstrates the application of this methodology to optimize solids concentration in ball milling of an iron ore

Read More

Ball Mill - an overview ScienceDirect Topics

The minimal magnitude of ball size is calculated in millimeters from the equation: where db.max is the maximum size of feed (mm); σ is compression strength (MPa); E is

Read More

(PDF) Grinding in Ball Mills: Modeling and Process

2012年6月1日 A ball mill is a type of grinder widely utilized in the process of mechanochemical catalytic degradation. It consists of one or more

Read More

Ball milling as a mechanochemical technology for fabrication

2020年9月1日 The planetary ball mill involves the generation of both shear and impact forces (Dash et al., 2016), which is commonly used in previous studies. The equipment

Read More

Investigation on the particle size and shape of iron ore

2023年12月14日 Abstract: An effect of a grinding method, that is ball mill and high pressure grinding rolls (HPGR), on the particle size, specific surface area and particle shape of an

Read More

Process Control of Ball Mill Based on MPC-DO - Hindawi

2021年7月26日 In this paper, different from the traditional two-input-two-output model of the ball mill grinding process, a three-input-three-output system considering the influence

Read More

Structural changes in iron powder during ball milling

2010年9月1日 Since iron and its alloys are backbone of today's structural materials and due to its high use in powder metallurgy, iron is chosen for the present study. 2.

Read More

Mechanistic modeling and simulation of grinding iron

2021年11月1日 Based on the machine learning method, this study analyzed the full process parameters (i.e., ball mill power, fresh ore feed rate, hydrocyclone feed pump

Read More

Investigation on the particle size and shape of iron ore

2023年12月14日 Investigation on the particle size and shape of iron ore pellet feed using ball mill and HPGR 909 areas of 500–1600 cm2 g-1.The concentrate must therefore be re-ground in order to

Read More

Comminution and classification technologies of iron ore

2022年1月1日 There are many different types of grinding mills that process many types of materials. 8.3.2.1. ... Ball mills are filled up to 40% with steel balls (with 30–80 mm diameter) which effectively grind the ore. ... While there are not HIG mills operating in iron ore applications, globally this technology is used in copper and gold circuits to ...

Read More

New insights into ball-milled zero-valent iron composites for

2023年1月20日 The process for preparing composites by ball-milling method is relatively complex. Ball-milling time and speed, grinding balls and ball-material ratio, process control agent and the type of ball mill are all parameters that require careful consideration prior to experimentation (Li et al., 2009; Ambika et al., 2016; Wang et al., 2022).

Read More

The Effect of Grinding Media on Mineral Breakage Properties

2021年12月11日 The breakage and liberation of minerals are the key to fluidized mining for minerals. In the ball milling process, steel balls function as not only a grinding action implementer but also energy carrier to determine the breakage behavior of ores and the production capacity of the mill. When ground products present a much coarse or much

Read More

(PDF) Grinding Media in Ball Mills-A Review - ResearchGate

2023年4月23日 One of the most used tumbling mills is the ball mill. This paper reviews different types of grinding media that have been developed and improved over the years and their properties. Also reviewed ...

Read More

Ball Mill - an overview ScienceDirect Topics

Planetary ball mill was used to synthesize iron nanoparticles. The synthesized nanoparticles were subjected to the characterization studies by X-ray diffraction (XRD), and scanning electron microscopy (SEM) techniques using a SIEMENS-D5000 diffractometer and Hitachi S-4800. ... However, high-energy ball mill is an efficient process for ...

Read More

Buy Cast Iron Grinding Balls Properties of Cast Iron Ball

The Cast iron grinding ball is excellent in surface quality, toughness, and resistance to impact and abrasion. It won't crack and lose circularity quickly. Grinding media is used in ball mills to pulverize or mix materials into powders The forged steel grinding ball must use super wear-resistant material to ensure abrasion resistance. Benefits include being able to be

Read More

Mechanistic modeling and simulation of grinding iron

2021年11月1日 Various approaches have been used over the years to describe quantitatively ball milling, with different levels of success.The present work presents the application and validation of a mechanistic model to describe ball milling of iron ore pellet feed. The approach started by estimating selected parameters describing the ore

Read More

The design and optimization process of ball mill to reduce

2020年11月16日 The balls to powder ratio (BPR) and powder type were investigated in relation to the particle size. The study showed that the combination of the BPR and powder type affects the particle size result. The optimum of BPR at 12 with the number of balls is 60 pieces, and the filling rate is 10.13%. The result shows that the horizontal ball mill able ...

Read More

Ball milling – A green and sustainable technique for the preparation

2022年1月1日 Ilmenite is a naturally available mineral that is highly applicable in the synthesis of pure TiO 2.Titania mainly presents in four polymorphs as rutile, anatase, brookite and TiO 2 –B. Titania could be mined from minerals such as ilmenite, leucoxene and rutile among which ilmenite is the main source. Ball milling is a mechanical activation

Read More

Mechanochemistry for ammonia synthesis under mild

2020年12月14日 The process is illustrated schematically in Fig. 1 and Supplementary Video 1.Ammonia is synthesized via ball milling using iron powder as the catalyst. The entire synthesis process can be divided ...

Read More

(PDF) Grinding in Ball Mills: Modeling and Process

2012年6月1日 A ball mill is a type of grinder widely utilized in the process of mechanochemical catalytic degradation. It consists of one or more rotating cylinders partially filled with grinding balls (made ...

Read More

Ball Mills - 911 Metallurgist

2017年2月13日 In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment. In present-day practice, the ore is reduced to a size many times finer than can be obtained with crushers. ... Grinding Media Ball Mill Liners. Balls are made of cast-iron, high-carbon, and chrome steel. Cast-iron

Read More

Ball Mill Ball Mills Wet Dry Grinding DOVE

2 天之前 DOVE small Ball Mills designed for laboratories ball milling process are supplied in 4 models, capacity range of (200g/h-1000 g/h). For small to large scale operations, DOVE Ball Mills are supplied in 17 models, capacity range of (0.3 TPH – 80 TPH). With over 50 years experience in Grinding Mill Machine fabrication, DOVE Ball Mills as ...

Read More

Wet ball milling of niobium by using ethanol, determination

2021年11月17日 This study investigates the effect of using ethanol as the process control agent during the wet ball milling of niobium (Nb). Dried nanocrystal Nb powders, of high purity, with particle sizes ...

Read More

Mechanical Milling: A Superior Nanotechnological Tool for Fabrication ...

2021年9月24日 Mechanical alloying (MA) is a typical solid-state process that occurs at room temperature between powders of diffusion couples utilizing various types of ball mills. Ball milling has evolved over the last five decades from a standard technique in mineral dressing and powder metallurgy, where it was primarily used for particle size reduction

Read More

Optimization of Solids Concentration in Iron Ore Ball Milling

2019年6月18日 Important advances have been made in the last 60 years or so in the modeling of ball mills using mathematical formulas and models. One approach that has gained popularity is the population balance model, in particular, when coupled to the specific breakage rate function. The paper demonstrates the application of this methodology to

Read More

Direct Mechanocatalysis: Using Milling Balls as Catalysts

2020年4月21日 Catalytic reactions in ball mills range from C−C cross-8 and homo-coupling 9 to Lewis acid and base chemistry 10 and C−H ... ball, exhibiting a completely different composition and requirements than conventional catalysts; 3) the milling process, ... Iron. Platinum. Rhodium. Alloy. 1.4301 (X5CrNi18-10) 1.4104 (X14CrMoS17) PtAu10. PtCu4 ...

Read More